Who Was Henri Baigent?

Henri Baigent was born as Henry Cyril Baigent in Dagenham, Essex, on the 5 th January 1909 to William Baigent and Janet Bird. He was the second of three sons and Muriel was his elder sister. He was a descendant of the Baigents of Rotherwick, who were descendants of a Huguenot family who had escaped persecution in France, around the middle of the 17th century.. His two brothers were Eric, the elder, and Keith, the younger.

Their father, William was a very hard man, who worked as a gas fitter, gunsmith and locksmith. The latter meant that he was often called upon to do 'jobs' for the local Police. William's brother, Herbert, had been murdered with a pitchfork, an agricultural tool which was used for throwing bales upon to the haystacks. William frequently beat his sons, particularly when he was drunk, which was most of the time. His wife had a very tough time with him but he was basically frightened of her as she was like a Jack Russell terrier, tiny, only five foot one inch tall, and very bright. She usually outwitted him, but she was also very strong in will and muscle, and with a heap of intelligence. Although she was so slight in frame she would physically haul him over the threshold into the house when she found him on the doorstep, drunk, after an evening in the local. This was not uncommon behaviour at the time in the family life of the manual work-force.

William was also very greedy and would eat his favorite dish while his family would have to have basic fare, sometimes nothing but bread. He was particularly fond of cods'-roe, which, for those of you who have not enjoyed this strong tasting savoury, is sausage-shaped and tastes a little like cheap caviar. He would measure the roe and make a note of its length before he went out, and would check the length when he returned. His sons also liked this morsel and found that if they rolled it between two smooth boards it would lengthen and after carefully cutting it back to its original length would share the remains. Such was the environment that Henry grew up in that he and his siblings were bound to be tough and somewhat crafty. This was to have a considerable effect on their later lives.

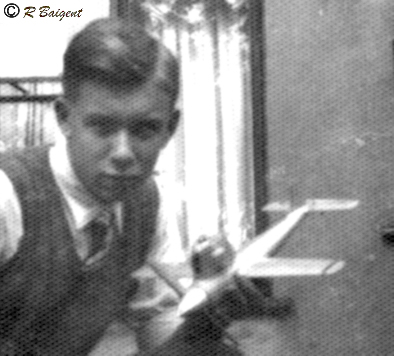

One day I was visiting Tunbridge Wells with my father when we met one of his schoolmasters. The master told me that Henry was very good at painting and drawing at school, which was a strong trait in Henry's make up during his adult years. It was very difficult to get work at all in his early years and after marrying Daisy May Osborne he had to do whatever he could find to bring in an income. I had arrived in the world rather earlier than convenient and this put even more pressure on him to find an income. He worked variously during the 20's and 30's as a bus driver, a lawn-mower sales-manager, a builders' merchants manager, and a fireplace-surround designer and maker. Of the latter, I first saw his un-named design folio when I built my first home after WW2, and it was really very fine. I chose a 'Tonbridge' fire-surround from it without realizing it was designed by my father until I had installed it in our bungalow and I asked the supplier why it was called the Tonbridge, then I was told the foliowas hi. We had lived in Tonbridge before moving to Bournemouth in 1935, hence the name.

He was always doing something with machinery in his spare time. Sometimes it was full-sized internal combustion engines or anything that would earn a few shillings. Just prior to the Second World War he made a treadle-lathe by converting a sewing machine. On this he made a 0-1 inch micrometer which was accurate to less than half-a-thousandth of an inch over the one-inch range. The threads he cut with a hand chaser. It was this that opened the door to an engineering career for him as the Armaments Inspectorate awarded him an A1 Certificate for this achievement.

The war, and the need for the urgent production of weapons, came just at the right time for Henry. He started up and took charge of an experimental equipment workshop making munitions for the war effort. His workshops soon were producing work of a very exacting nature, at a frantic pace. They were frequently sought out to do difficult jobs when other workshops had problems that they could not solve. Many of his work force worked long hours of overtime, while he worked most of the day and a large part of the night, except when he was called for duty as an Air-raid Warden on some nights. Bournemouth was lucky, it did not see much bombing but we could see the fires in Southampton, thirty miles away, from the roof of the workshops, when that town were blitzed by the Luftwaffe in 1941. Due to his pre-war activities, Henry had some contacts in the pottery towns and the 'Black Country'. Through these contacts, he located some used machinery which he was able to overhaul and put into use in the new workshops. He took me with him sometimes. He managed to borrow an Austin 16 in fine condition except all the four tyres were bald down to the canvas. On one trip we went 200 miles and then, within a hundred yards of home when all four punctured on our unmetaled road. We had to run on paraffin to save petrol, this was illegal, so my father devised a system where he could change over to petrol when he was not on the open road. So I was given the job of keeping an eye on the rear in case a policeman detected the smell of the fumes.

When the European Sector of the war ended, the the UK Government decided to remove support for the workshop and redirected Henri to work in a Radar Establishment under the 'Directed Labour' scheme. Here he made experimental wave-guides.

During 1945 he became

a free man. He was discharged as he was suffering with respiratory problems.

He had suffered with these ever since he had worked in the Crystalate Company

works pressing 78 rpm records in a moulding machine. The dust was very sharp, fine

and insidious and the workers had no protection. Health and safety was

ignored in those very hard days, and many fine men were afflicted with no

compensation, mostly dying quite young.

Around 1945, when he was free to do so, Henry became more active in advising me, and helping me, with my interests in designing, building and flying model aeroplanes. Model engines were in short supply and mostly were brought over from the United States. He promised me that he would make me one, but the project grew and grew until he had built the first known three-cylinder in-line model diesel engine of about 10cc capacity. It did not work at first but he spent most of three weeks, full time, except for sleep and meals, making modificationts and pulling the starting chord until it fired. After a few more days of rebuilding and pulling, it burst into a short song. I heard it and rushed into the workshop to see and hear the next burst. Henry was standing there exhausted but absolutely delighted. I think there were tears in his eyes, they were certainly sparkling. Weeks of development followed. His younger brother, Keith, who had much more technical knowledge, had said that it would not work, as it would be too difficult to establish seals between the three crankcases on such a small engine, absolutely essential for a 2-stroke multi-cylinder. This was sound advice, but Henry managed to solve the problems with much attention to detail. During this time my mother saw very little of him except for rapidly taken meals. Much later, this first engine was converted into glow-plug mode, and later, into a petrol engine. It had a very chequered history and was finally installed in a 1/8 th radio-controlled model of Rob Walker's Aston Martin DB2 . The last I heard of this model was that Rob had sold it at auction for £1500. If only I had known. Does anybody know where it is now?

the 3-cylinder racer that appeared in the 'Sphere' magazine

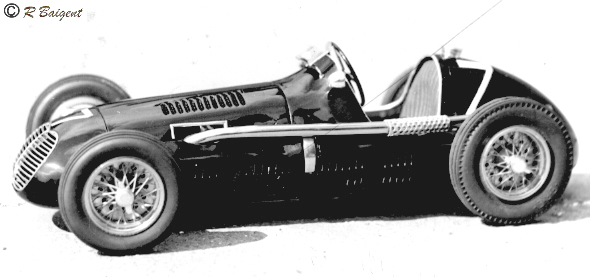

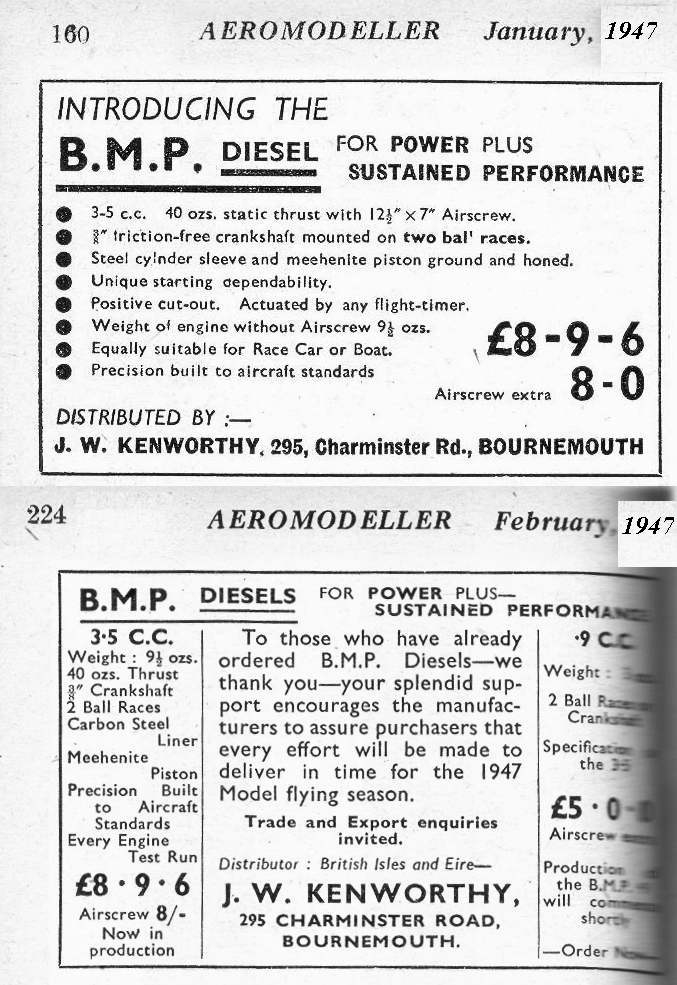

With the knowledge and experience that Henry had gained from the three-cylinder he decided he would then build me a model diesel engine to power an aircraft that I was planning to build. For some strange reason he decided to make it 3.5cc, not in any recognized class of competitions of the time, and what is more, it was too powerful for my design. He decided that it would be a great improvement to fit twin ball-races on the crankshaft, this was the first time that this configuration of bearing had been used in a 2-stroke diesel engine. It was very successful and it was a feature of most of his future designs. He suggested to some members of the board of a precision engineering company that it would be a great success if they produced it in quantity, because the market was wide open for an all-alloy design. Local modellers were eager to get their hands on one. It was at this time that members of the local model club christened him Henri and pronounced his name as 'on-ree bay-jon', pr. Bay as in curved beach and jon as in gen darme . Henri was amused and it became normal to call him 'on-ree'. This was quite a good sobriquet and with some caché , as later he found it amusing but comfortable that prospective customers thought he was French, which was thought to be synonymous with Bugatti, Hugo Tanin, and other exciting names. However, it was quite a while before he traded officially as Henri.

To produce the new engine, a new company was formed with the owners of a precision engineering company and Henri as a co-director. The engine went into production in small numbers to test the market. The second batch was much larger, about 200 units. The company was called The Bijou Model Productions or BMP for short.

These engines are listed here: www.antiquemodeler.org/adl/sam-engines.htm under SAM Legal Pre-1950 Original Diesel Engines as B.M.P.21 3.5cc (1947) and B.M.P. 0.9cc (1948).

The following year I wanted to power a small control-line stunt aircraft, so a 0.9cc was developed. We had become very much involved in flying control-line (U-control) and flew frequently on Queen's park, Bournemouth, a local golf course. Also, we flew and raced at Holmsley Airfield, a disused wartime bomber station in the New Forest. We found that it was a big mistake to choose 3.5cc as a size because competitions were in the main categories of 2.5cc, 5cc, and 10cc, this was strange because the market was led by the United States where the units were the Imperial Standard of cubic inches! Demand for the 3.5cc was dwindling so production was decreased. Finally the company was dissolved even though we were developing the cylinder into a 5cc size, the prototype of which I still have in working condition and is pictured below:

This is the prototype 5 cc, developed from the BMP 3.5cc that I describe below. It was this beast that was the power unit for the World Seaplane Endurance record which the legendary Lt Col C E Bowden set in the forties at Poole Harbour, Dorset, England. We made special large fuel tanks for him. He also used it to power boats competitively. Before the advent of small add-on motors like the 'Cyclemaster' I attached it to my sisters bicycle and drove the front wheel via a knurled drum and achieved 15 mph. along a flat path. This engine has seen some fun! The crankshaft had twin ball-race bearings. I also powered a control-line aircraft called 'The Barnstormer (from the US) with it. It pulled me nearly off my feet!

My Full-Time Involvement.

Until the summer of 1948, I worked under his wing in my long school holidays, learning what I could from the master. He would repay me by providing materials for my model aircraft. I had not decided on a career. He approached me with a proposal to work for him full-time until 'something turned up'. Since watching the Battle-of-Britain 'dog-fights' during the war I was keen to go into the RAF to fly. I asked him what the terms of reference were! He said, "My terms are, every morning that I go into work at 5.30am, you must have the workshop warm for me, and if you fail just once, I will sack you". He offered to pay me two-pounds-ten shillings per week for six full working days, with some unpaid overtime. One pound ten-shillings of that I would have to give to my mother for my keep." I agreed to these terms, as I had worked with him before as I grew into adolescence, and he had taught me so much. I was heavily into aero-modeling, being the Secretary of the School Model Club. I had a superb workshop in a converted glass-house. I studied flight and designed a lot of my own models. It was lack of enthusiasm for rubber-powered flight that caused me to pester Henri to make me a petrol engine to power my aircraft, as I was very keen to build for control-line (US. 'U-control') flying. This was the start of a very interesting period in my life during which I was to come to know how hard and demanding my father was in the struggle for excellence. Little did I realise how far this would develop over the years ahead.

It was beneficial to us both as I had worked part-time, under his wing, since a boy. Before leaving school, I had worked with him during the long vacations our school enjoyed. He was so exciting to be with, because there was always some new project with new problems to be solved. Never was it boring, just very demanding.

The Workshop Environment.

The workshop was distinctly malodorous and I am often taken back there when I visit various establishments. When entering, you were presented with the strong pungent smell of hot rubber and with this there was the urinal smell of liquid Latex. There was Acitone and Acetate solutions and cellulose paints from the spraying with no extractor fans. Just spray and open the front and rear doors after! We made our own fuels from mineral oils, methylated ether, amyl-nitrate and Castrol. There were no fire extinguishers in those days, just a large bucket of water, and if available, a bucket of sand. The exhaust fumes were always around in the air. There were the fumes from evaporating Jeyes Fluid which we frequently used for slurry when machining. On a hot day the cedar-wood in the workshop cladding was a great relief, but the workshop got unbearably hot as it had no windows and the roof was black bitchumen, which reflected no heat. So one of my jobs was to harvest elder tree branches and lay them over the roof to keep it cooler. As they died off and rotted they smelt awful too. Health and Safety was never an issue in those stark post-war days. However, I felt very lucky to able to work one-on-one with such a master. Most days were a blur of activity. When I look back to those times, I wonder how we did so much in such a short time. There were moments of relaxation, but they were not scheduled. They usually occurred when we had visitors to the workshop or if we had reached the end of a long struggle. It does sound as though it was all work and no play, but that was not the case. My father had a serious physiogmany and a very focused application to his work, but he had a good sense of humour. Laughter could be heard frequently coming from the workshop, and he was known to play pranks on visitors. When the slot-racing track was running, there were shouts and cheers emanating from the workshop. We had one particular visitor that I always looked forward to visiting us, the great Joe Kenworthy. Joe was so generous. He would always encourage me in an avuncular way and never failed to bring me a useful present of pre-war samples of Japanese aircraft parts. Bamboo ribs and Bamboo propellors and banana oil. Silk coverings and tissue to die for. He gave me books to study aeronautics and engineering. His knowledge was immensely valuable and he shared it with me generously. Joe won the prestigious international Wakefield Trophy in 1933 for rubber-powered flight with a model of his own design to a demanding set of rules. see http:// www.fai.org/aeromodelling/f1/wakefield/193 3 . He offered to take on the agency for the BMP engines as can be seen here:

The production BMP 3.5cc Diesel

These engines are listed here: www.antiquemodeler.org/adl/sam-engines.htm under font size="3" face="AvantGarde Md BT">SAM Legal Pre-1950 Original Diesel Engines as B.M.P.21 3.5cc (1947) (but I can not remember it having the code '21')

A lot of materials and tools were abandoned at the end of the European phase of World War II. Henry gathered them up from the scrap-yards and carried them home to his workshop. Rods of Mehanite and stainless steel (S11) was in abundance plus aluminium alloys of all sorts in various forms such as sheet material (L4, etc) of different gauges and rods, and tubes. But, although the drive for the war effort was over, Henri was seconded to work on the making of wave-guides at a local radar research establishment. The Ministry of Works called this Directed Labour, but really it was just cheap labour. The staff at the establishment were encouraged to join the club at the 18-hole golf course adjacent to the works at a subsidized fee, so it was some compensation. Henri was hooked and went from a ‘rabbit’ i.e. a raw novice, to a regular competition winner in a very short time. He concentrated on his short game, around the green, which gave him a great advantage. He used to have a saying, ’one on the fairway is the same as one on the green!’ He bought second-hand pre-war hickory clubs, a mashie (5-iron) and a niblick (9-iron). Why on earth did we manage to dump those wonderful Scottish expressions for a load of boring numbers? He repaired and remade them, and paid for his golf-balls with funds earned from the Club Professional for helping with club repairs. Then he cast his own putter in alloy! (see Henri the Inventor). Then he rescued an old Brassie (2-wood) and repaired it, so he had a wood! His game around the green was special, he always maintained how important that was. When I borrowed a set of clubs from the Professional and tried to smash my ball to infinity but it finished up nowhere, he harranged me. We had such fun in those days especially with the very entertaining, and somewhat mad, Bill Gilbert.

We did our own casting of metals in the wooden workshop, which was fraught with danger! The crucible was made from 5in outside diameter mild-steel tube, about 5in long, and having walls of about 3/8in faced off at top and bottom. To this was screwed a plate of 3/8in mild-steel with a very snug fit. This formed a cup-like crucible. The hot Tortoise stove was topped up with boiler-fuel (Anthracite) and given a powerful draw by opening the front flap fully. The stove was exhausted by a 3in diameter metal stove-pipe which rose through the wooden roof to a point about 3ft above the bitchumen. The fumes were acrid and one could hardly breathe as the pipe leaked. I dread to think what today’s authorities for health and safety standards would say. Not only for the fumes but the workshop was made almost entirely of wood, clad mostly in ship-lap cedar! When the stove was red-hot the lid was removed and the crucible placed into it, forming a snug fit. Then everything was heated to the same temperature. At this point, off-cuts of aluminium (aluminum) were placed into the crucible and heat applied until the aluminium became fluid. The surface would skin over due to the gases present and impurities in the metals. This had to skimmed off just at the last moment before pouring into the mould which had been prepared well in advance including pre-heating. The fluid had to be poured really carefully and smoothly to prevent air-bubbles forming and ruining the whole job. We often used old car pistons for alloy parts. As the pouring was done we had to tap the mould with a hammer to remove all the air-pockets as, in most cases, some could be found during the late stages of careful machining and that was wasteful in workshop time. All the patterns and most of the moulds were made in Henri’s workshop. Brass was successfully poured at times, as in the Delahaye radiator for Rob Walker which I cast twice in case of faults in the form of air-bubbles, but I can’t remember casting iron in that workshop. There was a local foundry that would make cast-iron parts for us if we required them, but we made all the patterns in box-wood ourselves. This wood has very few variations in its cellular structure and a very fine grain, so it could be shaped very accurately.

The 1 cc. prototype diesel engine

I wanted a smaller engine to power a small control-line stunt aircraft that I had designed and I pestered Henri to make me one. He said that I had to do it myself. I was always pressing for crankshaft induction for the engines but Henri was not so keen due to some problems with manufacturing and machining tolerances. He was also concerned that the crankshafts would not be able to take the heavy landing that came with control-line flying particularly stunt aircraft with no undercarriage where the plane would have to be brought into land on its belly. We would arrange the propeller to be horizontal when the motor stopped by positioning it relative to the stroke by fitting the propeller blade strategically. This did not always work smoothly, and hence even robust crankshafts did get bent fairly frequently, that was a seriously costly for modellers. I decided to go with my convictions so chose crank-shaft induction, despite the objections. I also went for as light a unit as I could. It was fairly successful but never developed and was dropped in favour of the more robust BMP 0.9 prototype with direct induction and twin ball-race bearing like its 3.5cc big brother .

the BMP 0.9cc production model

These engines are listed here: www.antiquemodeler.org/adl/sam-engines.htm under SAM Legal Pre-1950 Original Diesel Engines as B.M.P. 0.9cc (1948).

The ERE 2.5 cc. development specimen that exceeded the control-line speed record in testing while powering the 'Speed-job' here, nearly all spinner and engine! All-up weight only 8oz with a full tank!

These engines are listed here: www.antiquemodeler.org/adl/sam-engines.htm under SAM Legal Pre-1950 Original Diesel Engines as E.R.E. 2.48cc (1948)

When the first diesels were designed, it did not seem to be so important to constrain the power-to-weight ratio. Time was of the essence as the modellers were pressing hard to find any engines. The UK was suffering after a major war and it was a dark hour still, but there was a chink of light on the horizon. Many veterans were returning to a much less exciting life. They looked for pastimes and hobbies that would lighten their lives. Money was in short supply, and transport was sparse. We would look at the magazines from the United States with envy as the modellers there were able to choose from a large range of engines. because they could manufacture and sell in greater quantities they were able to justify 'die-casting' while we had to use sand-moulding due to the lower number of unit-sales. Thus, our engines did not have the smooth and neat appearance of those from the States. We gamely fought to catch up with our development. We were lucky that most of the engines that were imported were either petrol or glow-plug. Most of the owners of the American imports were proud as peacocks and thought they were invincible, but we proved that those forms of igbition were not so superior to our compression-ignition engines.

The second phase of development demanded a new and fresh approach. The power-to-weight ratio was considered for an increasingly competitive market emerging around 1947. Crankcase induction won the day and the integral fuel-tank was dropped. At this time, it was becoming obvious that the BMP production would cease, so an amicable agreement for Henry to leave the company ensued and Henry put all his efforts into the new engine, the ERE 2.5cc. This engine was optimized for the burgeoning Round-the-Pole car racing and to be completive in competition model aircraft. We had a lot of success with our engine against the Oliver's in the car field and the eponymous ED Racers in the flying field, although both of those engines were very fine and successful.

During the morning practice, at the 1949 Nationals at Radlett, Herts, the 'speed-job' exceeded the national speed record for the 2.5cc class by a healthy margin, but my girl friend (of the time) sat on the 1/64 in. ply tailplane in the back of my uncle's car and rendered it irreparable just before a serious record attempt . There was no way that I could do an edge repair and I had no spare, and no girl-friend after that! It took a while to get over that loss; the plane, I mean! I felt worse because she was not on the back-seat by herself.

At those Nationals, our friend and retail agent, Pete Cock won the Control-line (U-control) Stunt Gold Cup 1949. He had changed over from an ED to our ERE 2.5 cc diesel motor and a stack of my own special ultra-thin propellers, which the blades were translucent on the outer halves, one could almost see through them, but of course, they were easily damaged on landing. We had to set the engines to stop with the blade horizontal as there was no undercarriages to land with. Most competitors were using a jettinisable trolley for take-off. Generally we advised starting the engine with an electric motor with a rubber cup on the spinner. After receiving deep injuries on my index finger I found a way of starting by flicking the leading edge of the propeller against compression in an anticlockwise direction, and it would fire back and start in the correct direction. I still carry the scars! We set up a thrust-measuring device to achieve the best propeller forms. It was simple and a great help. It was just a radial arm mounted on ball-races with a spring load, which we calibrated with graduated pendulous weightsDevelopments in Car Racing

Around this time we started racing model cars 'around-the-pole', or RTP for short. The car was tethered on the side and rear to a pole in the centre of a flat circle by a wire cable and yoke. After a year or so, speeds of up to 70mph were achieved by 2.5cc cars in the right conditions. I deal with RTP separately here: Round the Pole Racing.

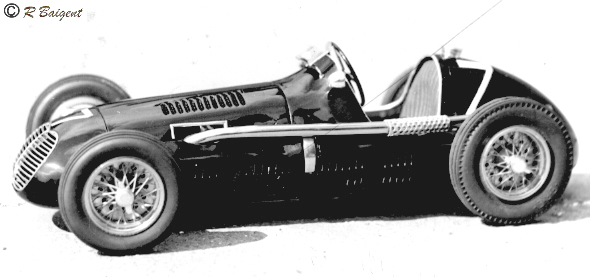

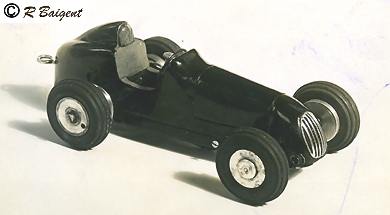

1930s Austin Racer, the first powered model-racing car that Henri made

The first RTP cars, the 1930s 'Works' Austin, the first of which is shown here, was carved out of several glued-together blocks of mahogany, subsequent models were mostly beaten aluminium (aluminum), except for the Delahaye and the Delage . Those two models, and a couple of Bugattis and maybe some others that I can't bring to mind, had hardwood bottom trays. Those early years were totally frantic.

It was quite a distance to the remote airfield where we were regularly testing new models and modifications. Henri had an idea that we could have a circular round-the-pole track in our garden. He set me the job of making moulds for the manufacture of curved segments of track about a yard long. I would then be expected to cast quick-setting 'Fondu' cement slabs in them. Location dowels were set in the ends to achieve a level track, and the surface was kept very smooth by using an aluminium sheet base in the mould. this was dosed liberally with 'Jeyes-Fluid' (an emulsifying oil) as a releasing agent. We usually used this fluid as a 'slurry' for turning mild-steel parts, and it worked well. The track was reasonably successful. However, while running a 5 cc. car at speed, the centre-pin pulled out and the car flew off and damaged some fence that belonged to a neighbour. However, we were lucky that no-one was injured. There was another snag, the capricious English weather. We had to call off trials, sometimes, due to rain or snow. This always led to considerable disappointment. Also, you could only do time-trials against a hand-held stop-watch, one car at a time. Henri thought there must be a better way where we did not have to rely on those stop-watches. Hence indoor track-racing was born, in this country, at any rate. For more about the later track-racing developments see here: Track Racing.

Early in 1948, we changed the slot attachment system for a monorail type, which was almost certainly the first attempt at rail racing. It was very successful and it took off very quickly as it was cheaper to make than the slot systems.

Henri found some large glass tanks which he set-up as plating baths. Chromium plating was not very successful but copper and nickel was always available. He somehow managed to obtain the bath fluids and the cathodes and anodes to make the baths. There were linked stacks of vehicle batteries to provide the power. I was fascinated by the process, and the results, but did not fully understand how it worked at that time.

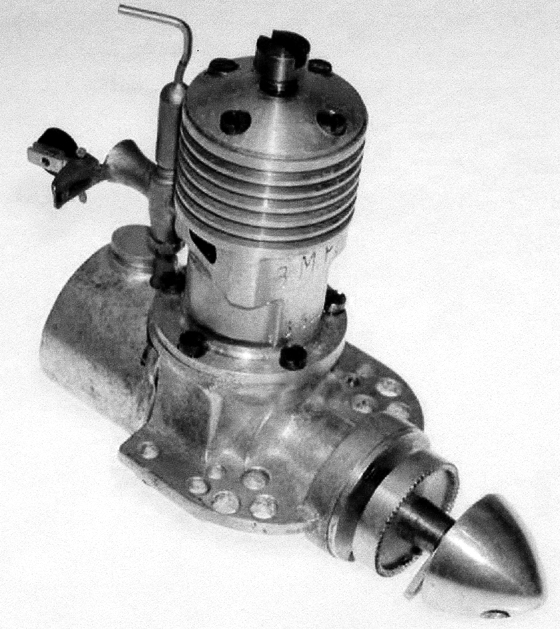

The wonderful little Mills 0.75cc. diesel, which I include as we used them with success when a track project demanded, and the picture may invoke memories for some older modellers.

Henri's Home-made Camera

As the 1940's drew to an end, cash was in very short supply. Henri had a beautiful ¼-plate double-extension camera which he took most of the early pictures with. I was sent with it to all the camera and pawn shops in the area, to try to raise some cash. The most I was offered for it was 5 pounds Sterling. However, it got us by while we waited for monies owed to us. During the 1950's, as funds were not available for a decent camera, Henri decided he would design and build one for himself using black acrylic plastic for the body shell and using a gun-site lens which his older brother Eric found for him. Eric was involved in lenses during the war so he was the man to help. Henri took many of the photos with it that I have included until he managed to obtain a Mamiya SLR during the early 1960's. It took excellent pictures and was very light and small. The aperture was set small in size so that only the best part of the lens was in use. This also increased the depth-of-field which had some advantages, but few disadvantages, in photographing models of this kind and other technical subjects.

Early Static Trophy Models

Not all models in these early years were powered. When John Cooper brought out his 500cc racer, Henri made a couple with the idea that they would be appropriate as trophies for the 500 class racing. Sadly, I have no idea what happened to them.

click on photos to enlarge: a note by Henri to Cyril Posthumus, on the reverse, says the tyres are temporary as the final mould is in the making. The wheels were diecast aluminium and the final tyres wider in section. The suspension and the rack-and-pinion steering all worked. 1/12 scale.